Beginning with How Fleet Maintenance Saves Companies Thousands Annually, the narrative unfolds in a compelling and distinctive manner, drawing readers into a story that promises to be both engaging and uniquely memorable.

This topic delves into the importance of regular fleet maintenance, highlighting cost-saving benefits, preventive maintenance strategies, monitoring and tracking systems, and the role of training and education in saving costs.

Importance of Fleet Maintenance

Regular maintenance of a company's fleet of vehicles is crucial for ensuring optimal performance, longevity, and safety. Neglecting to maintain vehicles can result in costly repairs, downtime, and even accidents on the road.

Preventing Costly Repairs

Proactive fleet maintenance, such as regular oil changes, tire rotations, and brake inspections, can help identify and address potential issues before they escalate into major problems. For example, failing to replace worn brake pads can lead to damage to the rotors, resulting in a costly repair bill.

Minimizing Breakdowns and Accidents

By adhering to a scheduled maintenance program, companies can reduce the risk of unexpected breakdowns that can disrupt operations and lead to delays in delivering goods or services. Moreover, well-maintained vehicles are less likely to experience mechanical failures while on the road, lowering the chances of accidents caused by faulty equipment.

Ensuring Compliance and Efficiency

Regular maintenance also helps companies comply with regulations and standards set by authorities. Keeping vehicles in top condition ensures that they meet safety and environmental requirements, avoiding fines and penalties. Additionally, efficient vehicles consume less fuel, saving on operational costs in the long run.

Cost-saving Benefits

Routine fleet maintenance plays a crucial role in helping companies save thousands of dollars annually. By investing in regular upkeep, businesses can prevent costly repairs, extend the lifespan of vehicles, and improve overall operational efficiency.

Preventive Maintenance

- Regular oil changes and filter replacements can prevent engine damage, reducing the risk of expensive repairs in the future.

- Checking and replacing worn-out tires can prevent blowouts and accidents, saving on repair costs and potential legal liabilities.

- Inspecting brakes and replacing brake pads can prevent brake failure, ensuring the safety of drivers and avoiding costly accidents.

Increased Lifespan

- Regular maintenance helps identify minor issues before they escalate into major problems, prolonging the lifespan of vehicles and reducing the need for premature replacements.

- Proper maintenance of engine components, such as belts and hoses, can prevent breakdowns and extend the overall longevity of the vehicle.

Preventive Maintenance Strategies

Preventive maintenance strategies are crucial in ensuring the longevity and efficiency of a company's fleet of vehicles. By implementing regular maintenance schedules and utilizing technology, companies can save thousands of dollars annually in repair costs and downtime.

Types of Preventive Maintenance Approaches

- Time-based Maintenance: This approach involves conducting maintenance tasks on vehicles at regular intervals, such as every 3 months or 5,000 miles, regardless of the vehicle's condition.

- Usage-based Maintenance: Maintenance tasks are performed based on the number of hours a vehicle has been in operation or the distance it has traveled since the last maintenance check.

- Predictive Maintenance: Utilizing technology like sensors and data analysis to predict when maintenance is needed based on the vehicle's actual condition and performance.

Maintenance Schedules for Various Types of Vehicles

- Commercial Trucks: Maintenance schedules for commercial trucks typically include regular oil changes, tire rotations, brake inspections, and fluid checks every 10,000 miles or every 6 months.

- Delivery Vans: Maintenance schedules for delivery vans may involve more frequent checks due to their frequent stop-and-go driving, including brake pad replacements every 20,000 miles and transmission fluid changes every 30,000 miles.

- Sedans: Sedans used for business purposes may have maintenance schedules that include oil changes every 5,000 miles, tire rotations every 10,000 miles, and regular inspections for wear and tear.

Role of Technology in Streamlining Maintenance Processes

- Telematics Systems: These systems help track vehicle performance in real-time, providing data on fuel efficiency, engine health, and maintenance needs.

- Predictive Analytics: By analyzing data from sensors and vehicle diagnostics, companies can predict maintenance needs before breakdowns occur, reducing downtime and repair costs.

- Mobile Apps: Maintenance apps allow drivers and fleet managers to schedule maintenance tasks, track service records, and receive alerts for upcoming maintenance needs, ensuring vehicles are well-maintained at all times.

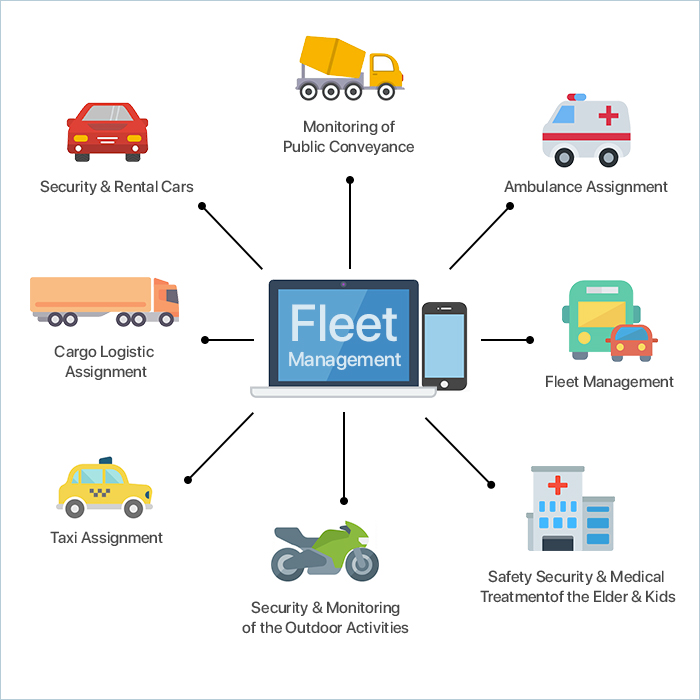

Monitoring and Tracking Systems

Monitoring and tracking systems play a crucial role in fleet maintenance by providing real-time data and insights that help optimize maintenance schedules and reduce costs.

Importance of Monitoring Systems

- Monitoring systems allow fleet managers to track the performance of vehicles in real-time, identifying any issues or potential maintenance needs promptly.

- These systems help in preventing breakdowns and unplanned downtime by enabling proactive maintenance based on actual data.

- By monitoring key metrics such as fuel consumption, engine health, and tire pressure, fleet managers can ensure optimal performance and efficiency of their vehicles.

Comparison of Tracking Tools

- GPS tracking: GPS tracking systems provide real-time location data, route optimization, and geofencing capabilities, allowing for efficient fleet management and monitoring of driver behavior.

- Telematics systems: Telematics combine GPS technology with onboard diagnostics to track vehicle health, performance, and driver behavior, helping in identifying maintenance issues before they escalate.

- Fleet management software: These tools offer comprehensive fleet tracking, maintenance scheduling, and reporting features, allowing for centralized monitoring and optimization of maintenance activities.

Optimizing Maintenance Schedules with Tracking Data

- Data from tracking systems can be used to create predictive maintenance schedules based on actual vehicle usage and performance, reducing the need for costly reactive repairs.

- By analyzing trends and patterns in maintenance data, fleet managers can identify areas for improvement, optimize maintenance intervals, and extend the lifespan of their vehicles.

- Real-time alerts and notifications from tracking systems enable quick response to maintenance issues, minimizing downtime and maximizing the efficiency of the fleet.

Training and Education

Training and education play a crucial role in ensuring that maintenance staff are equipped with the necessary skills and knowledge to effectively manage fleet maintenance operations. By investing in training programs, companies can improve the efficiency of their maintenance practices and ultimately save costs in the long run.

Specialized Training for Different Vehicle Types

- Specialized training programs for maintaining different types of vehicles, such as trucks, buses, or cars, can help maintenance staff understand the unique requirements of each vehicle type.

- For example, training on heavy-duty trucks may focus on engine diagnostics, brake systems, and transmission maintenance, while training on hybrid vehicles may cover battery maintenance and regenerative braking systems.

- By providing targeted training, companies can ensure that their maintenance staff are well-prepared to handle the specific challenges associated with different vehicle types, leading to more effective maintenance practices.

Continuous Education for Improved Maintenance Practices

- Continuous education programs, such as workshops, seminars, and online courses, can help maintenance staff stay updated on the latest maintenance technologies and practices.

- By continuously learning and adapting to new advancements in the field, maintenance staff can improve their maintenance practices, diagnose issues more effectively, and implement cost-saving strategies.

- Moreover, ongoing education can also enhance the overall skills and expertise of maintenance staff, leading to increased efficiency and reduced downtime for fleet vehicles.

Conclusive Thoughts

As we conclude our discussion on how fleet maintenance saves companies thousands annually, it becomes evident that investing in proactive maintenance not only reduces costs but also ensures the longevity and efficiency of a company's fleet. By prioritizing maintenance, companies can avoid costly repairs, breakdowns, and accidents, ultimately leading to substantial savings over time.

FAQ Resource

How often should fleet vehicles undergo maintenance?

Fleet vehicles should undergo regular maintenance according to a schedule based on mileage, usage, and manufacturer recommendations to prevent costly repairs and breakdowns.

What are some common preventive maintenance approaches for fleet vehicles?

Common preventive maintenance approaches include regular oil changes, tire rotations, brake inspections, and fluid checks to ensure optimal vehicle performance and longevity.

How can monitoring systems optimize fleet maintenance schedules?

Monitoring systems provide real-time data on vehicle performance, allowing companies to track maintenance needs, schedule repairs efficiently, and prevent unexpected breakdowns, ultimately saving costs.